Gen Set Cooling Pumps

Flexible Impeller Engine Cooling Pumps

JMP is specialized in manufacturing the HIGHEST QUALITY heavy duty raw water pumps, marine engine cooling pumps and spare parts for 40 Years! These are designed and manufactured especially for engine cooling applications. You can have CONFIDENCE that when you choose a JMP pump you are truly getting the BEST.

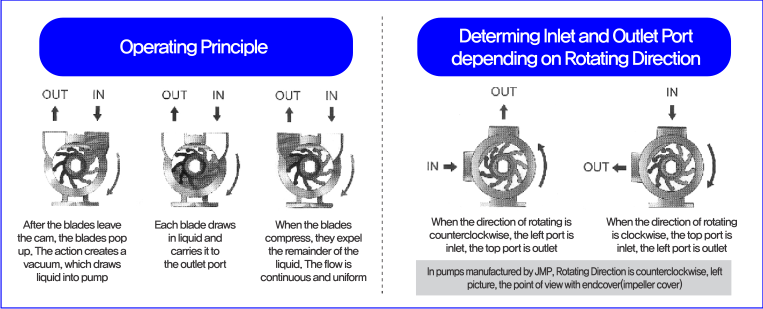

Flexible impeller pumps provide an efficient solution to most marine pumping needs. The primary advantage of a flexible impeller pump is its self-priming capability. As the blades of the impeller are depressed and rebound, they create their own vaccum, drawing fluid into the pumps (see operating principle)

Pumps with dry suction instantly lifts up to 3 meters, up to 9.5 meters when wet. Thus a flexible impeller pump being used in bilge, deck wash, or engine cooling need not be located below the water line or manually primed. An added feature of flexible impeller pumps is that they can pass fairly large particles without clogging or damaging the pump. This reduces the need for filtering the incoming fluid. A common feature of all flexible impeller pumps is that they cannot be permitted to run dry for more than 30 seconds. Both the impeller and the seals depend upon the water for lubrication and will soon burn out if run dry. Worn parts are easily replaceable, and service kits are available for all models.

For Good Pumping

Pipe runs should always be kept as short and straight as possible, avoiding rising and over obstructions, as this can create air-locks. Plumbing should be reinforced, non-collapsible hose fo the recommended size. Flexible impeller pumps must not run dry (no more than 30 seconds). Bilge pumps and water pumps in particular should always be fastened to the boat structure to ensure their permanent location. Mount flexible impeller pumps so that some water is left in the pumpbody when the pump is off; this will prolong impeller lif and speed priming. Pumps must be installed with the overboard discharge well above the waterline to avoid water syphoning back into the vessel.

Features Such As:

- Plug & Play Replacement

- Strong Body Heavy Duty Grade Casting

- Long Life Mechanical Seal

- Marine Grade Shaft (3X Series Non-Magnetic)

- High Performance and Long Life Flexible Impeller

- High Volume Flow Capacity

- Built-In Cam Housing

- Designed with Easy Replacement of Spare Parts

- O-Ring Seals at End Cover (Impeller Cover) Instead of Gasket

JMP MARINE . . ."THE ONLY ONE"

DIFFERENCE BETWEEN JMP FLEXIBLE IMPELLERS vs OTHERS?

- JMP Marine (JMP Corp) performs total "IN HOUSE MANUFACTURING" meaning that they do not outsource any part of the process, including materials, as all the other brands today must do. This ensures the highest standards of quality control making sure that their consumers, as yourself, have the utmost confidence and peace of mind that you are receiving a product without comprise. You will get the QUALITY & PERFORMANCE you are looking for and more!

- JMP Marine Flexible Impellers DO NOT USE HARMFUL CHEMICALS thereby ensuring the protection of our environment. Products are "ROHS" FREE (ROHS means "Restriction of Hazardous Substances).

- JMP has developed a unique formula taken over 40 YEARS OF EXPERIENCE producing an impeller mixture that has been specifically designed for seawater & raw water applications resulting in a much more durable longer lasting product vs the Neoprene and Nitrile of other brands today.

- JMP Marine goes a step further . . . in developing an added mixture they call "WAX BRANDING" which is infused throughout the impeller material and has aided in the result of an impeller that can last up to 3 times longer than all others out there.

- JMP Marine uses "BRASS INSERTS" vs stainless steel. Even though this does take longer, it produces a machined product that is of better quality resulting in a much MORE DURABLE LONGER LASTING PRODUCT