Product Description

Oberdorfer 104M Bronze Close-Coupled Centrifugal Pump (115V/230V 50/60Hz or 230V/460V 50/60Hz)

Uses: Marine Air Conditioning, Chemical re-circulation, chemical transfer, bicarbonate systems, de-ionized water systems, refrigerators, scrubber systems, detergent mixers.

Model: 104M

LEAD TIME is 1-3 days, Unit must be assembled to match specifications.

FEATURES:

- UP to 1440 GPH

- Max Flow = 53 Gal/min at 10FT

- Max Head = 51FT

- Up to 69,000 BTU

- 115V/230V 50/60hz Options

- Inlet: 3/4" FPT

- Outlet: 3/4" MPT

Oberdorfer close-coupled pumps use a standard NEMA C-Flange Jet Pump Motor with weld-on base and threaded shaft end to accept the pump impeller. Proper pump rotation is counterclockwise looking at the inlet end of the pump. Three phase installations must be checked for proper rotation when pump is installed as interchanging any 2 wires in a 3-phase system will reverse motor rotation.

Please note that the number of mounting screws have changed from 8 to 4 with the revision of the 104M series.

The 104M model has Rugged Bronze Construction with Teflon barrier seal to protect the bearings as well as reduce noise. Offered with a flexible discharge port orientation alongside multiple shaft and seal options for a variety of fluid and temperature uses.

Standard Mechanical seal is Nitrile rubber at 212F max temp. Optional FKM and PTFE seals are available for severe solvents, chemicals and elevated temperatures.

Maximum liquid viscosity is 2000 Saybolt Seconds Universal; however, the higher viscosity will lower the flow and require more HP. Higher viscosity fluids as well as particulate in the fluid will reduce seal life-expectancy.

These Centrifugal Pumps are NOT self-priming. The units must be installed for flooded suction (below liquid level). A foot valve in combination with a manual air bleed for vacuum on the suction side will allow suction lift to 15ft.

In centrifugal pumps the HP required will decrease as the pressure increases, a wide-open discharge uses maximum HP.

MODEL - MOTOR INFORMATION:

Revision model uses 4 Mounting screws / Old Model uses 8 mounting screw

NOTE : Our Default Choices come with Specific Motors - PLEASE CONTACT IF REQUIRING ANY CHANGES.

_______________________

Wet End:

Bronze Impeller, Nitrile rubber seal (optional FKM and PTFE seals), Monel Shaft or Stainless Steel(316SS or 416SS).

Max Internal Temperature: 212 °F (100 °C) Nitrile Standard Seal

_______________________

Oberdorfer REPAIR KIT NUMBERS:

- Oberdorfer p/n: 10720 Repair Kit is for Series 104M

- Oberdorfer p/n: 12173 Repair Kit is for Series 104MP

- Oberdorfer p/n: 10720 Repair Kit is for Series 104M-06

- Items included; 0-ring, Impeller, Seal Head, Seal Wearface/Seal Seat, Set Screw, Lip Seal.

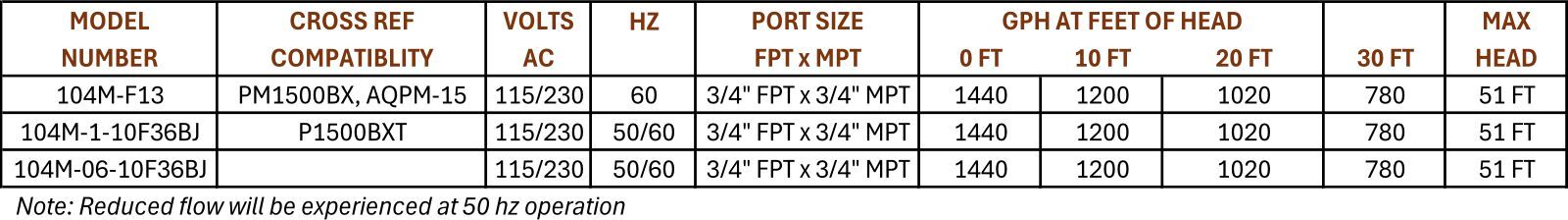

CROSS-REFERENCE MODEL(S) LIST:

Interchangeable Oberdorfer Models: OB104M-F13C / OB104M-F13, OB104M-F26C / OB104M-F26.

Replacement for Aqua-Air Models: AQPM-15

Replacement for Cruisair Models: PM1500BX, P1500BTX (Please Contact as this requires specific alterations)

_______________________

Oberdorfer PUMP DRAWINGS, CURVES, MANUAL & GENERAL INSTALLATION INFO

(PDF VIEW AND/OR DOWNLOAD)

- OBERDORFER 104M Series (115/230V) DIMENSIONAL DRAWING AND SPECIFICATIONS(View and/or Download)

- OBERDORFER 104M Series METRIC BRONZE PUMP OVERVIEW(View and/or Download)

- OBERDORFER 104M Series IMPERIAL BRONZE PUMP OVERVIEW(View and/or Download)

- OBERDORFER 104M Series BRONZE PUMP INSTALLATION AND MAINTENANCE(View and/or Download)

- OBERDORFER 104M Series CENTRIFUGAL SEAL REPLACEMENT INSTRUCTIONS(View and/or Download)